Izifaki khodi zomugqa we-HD20 ezinemba okuphezulu

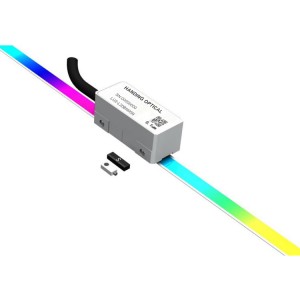

1. Uhlolojikelele Lomkhiqizo

I-steel belt grating yi-aithuluzi lokulinganisa ngokunembayakhelwe izinhlelo zokusebenza zokubeka umugqa kanye ne-angular ezimbonini ezahlukahlukene. Ihlanganisa ukwakhiwa okuqinile nobuchwepheshe obuphezulu be-optical ngokunemba okuphezulu nokuthembeka kwesikhathi eside.

2. Izici Eziyinhloko

Ukunemba kokulinganisa okuphezulu nokuphindaphinda okuhle kakhulu.

Ihlala isikhathi eside futhi imelana nezindawo zezimboni ezinokhahlo.

Isekela ukuhlanganiswa nezinhlelo ezizenzakalelayo nokulawula.

Idizayini yokulungiswa okuphansi kokwenza izindleko ngempumelelo

3. Imininingwane Yezobuchwepheshe

Okubalulekile:Insimbi engenasici eqinile.

Ibanga lokunemba:±3 µm/m noma ±5 µm/m (kuye ngemodeli).

Ubude obukhulu:Kufika kumamitha angama-50 (kungenziwa ngezifiso ngokuya ngezidingo).

Ububanzi:10 mm kuya ku-20 mm (amamodeli athile angahluka).

Isixazululo:Iyahambisanaizinzwa ze-optical ezinembile kakhulu(kufika ku-0.01 µm kuye ngokucushwa kwesistimu).

I-Operating Temperature Range:-10°C kuya ku-50°C.

Ibanga Lokushisa Lesitoreji:-20°C kuya ku-70°C.

I-Thermal Expansion Coefficient:10.5 × 10⁻⁶ /°C.

Ukuvama kwewashi:20MHz

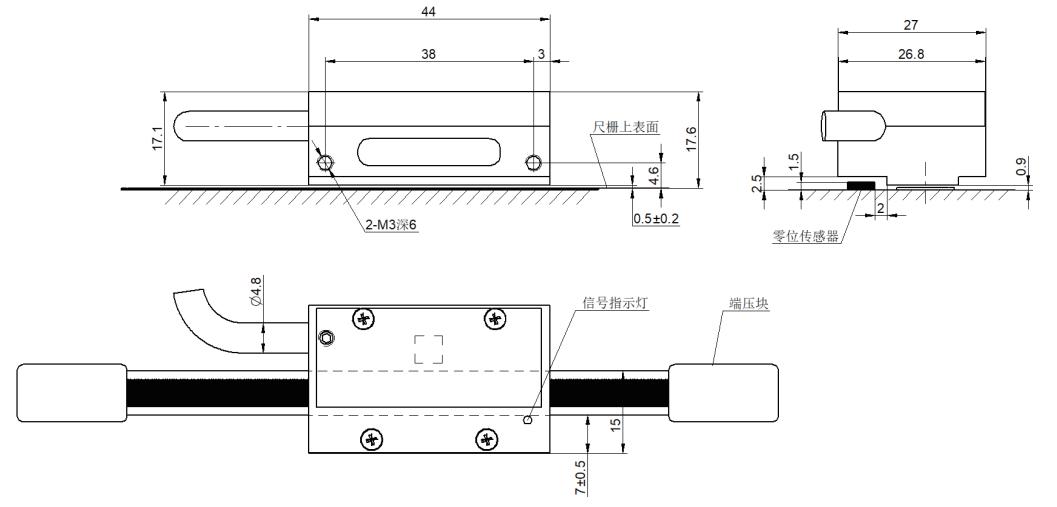

4. Umdwebo wobukhulu

Ubukhulu be-steel belt grating buchazwe kumdwebo wobuchwepheshe, ocacisa okulandelayo:

Umzimba Wokugaya:Ubude buyahlukahluka ngokusekelwe kumodeli (kufika kumamitha angu-50); ububanzi buphakathi kuka-10 mm no-20 mm.

Izindawo zokuhlala ezengeziwe e-Mounting Hole:Kuqondaniswe ngokunembile ukuze kufakwe okuphephile nokuzinzile.

Ubukhulu:Ngokujwayelekile 0.2 mm kuya ku-0.3 mm, kuye ngemodeli.

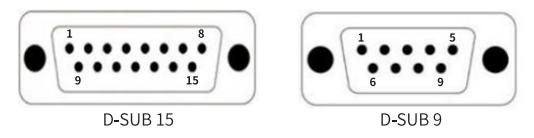

5. Imininingwane Yesixhumi se-D-SUB

Ukucushwa Kwephini:

Iphinikhodi 1: Ukunikezwa kwamandla (+5V)

Iphinikhodi 2: Umhlaba (GND)

Iphinikhodi 3: Isiginali A

Iphinikhodi 4: Isiginali B

Iphinikhodi 5: I-Index Pulse (Z Signal)

Iphinikhodi 6–9: Igcinelwe ukulungiselelwa ngokwezifiso.

Uhlobo Lwesixhumi:9-pin D-SUB, owesilisa noma owesifazane kuye ngomklamo wesistimu.

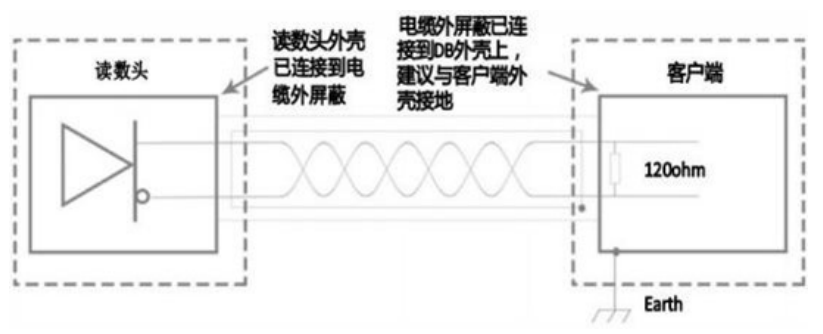

6. Umdwebo Wezintambo zikagesi

Umdwebo wezintambo zikagesi uveza ukuxhumana phakathi kwegridi yebhande lensimbi nesilawuli sesistimu:

Ukunikezwa kwamandla kagesi:Xhuma imigqa ye-+5V kanye ne-GND emthonjeni wamandla olawulwayo.

Imigqa Yesiginali:Isiginali A, Isiginali B, kanye ne-Index Pulse kufanele ixhunywe kokokufaka okuhambisanayo kuyunithi yokulawula.

Ukuvikela:Qinisekisa ukuthi isivikelo sekhebula sibekwe phansi ngendlela efanele ukuze kugwenywe ukuphazamiseka kozibuthe.

7. Imihlahlandlela yokufaka

*Qinisekisa ukuthi indawo yokufaka ihlanzekile, iyisicaba, futhi ayinayo imfucumfucu.

*Sebenzisa abakaki abanconyiwe namathuluzi okuqondanisa ukuze umise kahle.

*Qondanisa igridi ne-eksisi yokulinganisa, uqiniseke ukuthi akukho ukusonteka noma ukugoba.

*Gwema ukuchayeka ezintweni ezingcolile ezifana nowoyela noma amanzi ngesikhathi sokufakwa.

8. Iziqondiso Zokusebenza

*Qinisekisa ukuqondanisa okufanele nokulinganisa ngaphambi kokusetshenziswa.

*Gwema ukusebenzisa amandla eqile ekugayeni ngesikhathi sokusebenza.

*Qapha noma yikuphi ukuchezuka kokufundwayo futhi ulinganise kabusha njengoba kudingeka.

9. Ukunakekela kanye nokuxazulula izinkinga

Ukunakekela:

*Hlanza indawo egayiwe usebenzisa indwangu ethambile, engenalutha kanye nesihlanzi esisekelwe etshwaleni.

*Hlola ngezikhathi ezithile ukulimala komzimba noma ukungahambi kahle.

*Qinisa izikulufu ezixegayo noma shintsha izingxenye ezigugile.

Ukuxazulula inkinga:

*Ngezilinganiso ezingahambisani, hlola ukuqondanisa bese ulinganisa kabusha.

*Qinisekisa ukuthi izinzwa ezibonakalayo azinazithiyo noma ukungcola.

*Thinta abosekelo lwezobuchwepheshe uma izinkinga ziqhubeka.

10. Izicelo

I-steel belt grating ivame ukusetshenziswa ku:

*CNC machining kanye ezishintshayo.

*Amasistimu wokumisa amarobhothi.

*Amathuluzi e-Precision metrology.

*Izinqubo zokukhiqiza izimboni.

Izigaba zemikhiqizo

-

Ucingo

-

I-imeyili

-

Whatsapp

whatsapp

-

I-WeChat

-

Phezulu